The Largest Producer of Pulp and Paper in India

Introduction

The pulp and paper industry in India has a long and rich history, with the first recorded paper mill in the country dating back to the early 19th century. The industry has evolved significantly over the years, adapting to changing demands and technological advances.

During the early years of the industry, paper was primarily produced using rags as the raw material. This was a labor-intensive and time-consuming process, and as a result, the paper was a luxury item that was only affordable to a select few. In the late 19th and early 20th centuries, the introduction of wood pulp as a raw material revolutionized the industry, making it possible to produce the paper on a larger scale at a lower cost.

Over the following decades, the industry continued to evolve and expand, with the establishment of numerous paper mills across the country. The introduction of new technologies, such as the Fourdrinier machine, which allowed for the continuous production of paper, further increased efficiency and productivity.

Today, the pulp and paper industry in India is a thriving sector that plays a vital role in the country's economy. The industry produces a wide range of products, including printing and writing paper, packaging materials, tissue paper, and more, and is an important contributor to the country's export revenue. Despite facing challenges such as rising raw material costs and competition from imported products, the industry remains a key player in the Indian economy.

Application of Superior Quality Pulp & Paper Products

Pulp and paper products have a wide range of applications across various sectors, including:

Printing and Writing

Printing and writing paper is used in the production of books, newspapers, magazines, and other printed materials. It is also used in office settings for the printing of documents and other materials.

Packaging

Pulp and paper products are used extensively in the packaging industry, including the production of corrugated boxes, paper bags, and other types of packaging materials. These products are used to protect and transport a wide range of goods, from food products to electronics.

Construction

Pulp and paper products are also used in the construction industry, including the production of insulation materials and plasterboard.

Personal care

Tissue paper and paper towels are used extensively in the personal care industry, including in the production of facial tissues, toilet paper, and wipes.

Agriculture

Pulp and paper products are also used in the agriculture industry, including the production of seedlings and plant pots.

Retail

Retail stores and supermarkets often use paper bags and other pulp and paper products for packaging and carrying goods.

Overall, the applications of pulp and paper products are diverse and wide-ranging, making them an essential part of everyday life.

Production of Superior Quality Pulp & Paper Products

The production of pulp and paper products involves several steps, which can vary depending on the specific product being produced. However, the general process is as follows:

Raw material preparation

The first step in the production of pulp and paper products is the preparation of the raw materials. This typically involves chopping or grinding the raw materials, such as wood pulp or recycled paper, into small pieces.

Pulping

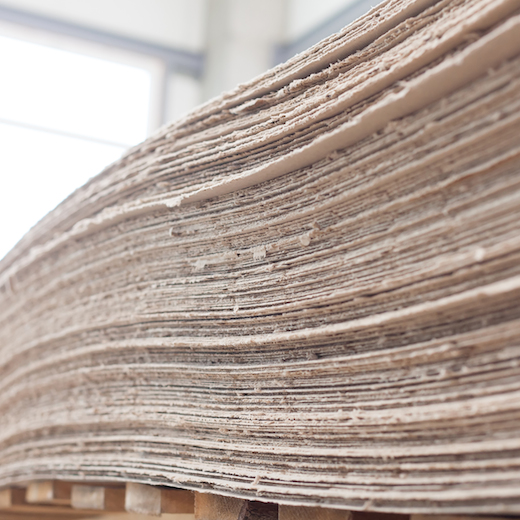

The next step is the pulping process, which involves breaking down the raw materials into individual fibers using chemical or mechanical methods.

Screening

After pulping, the fibers are screened to remove any impurities or contaminants.

Cleaning

The fibers are then cleaned to remove any remaining impurities or contaminants.

Bleaching

Depending on the desired end product, the fibers may be bleached to improve their appearance.

Forming

The fibers are then formed into sheets using a Fourdrinier machine or other equipment.

Drying

The sheets are then dried to remove any remaining moisture.

Finishing

After drying, the sheets are finished to give them the desired properties, such as smoothness or absorbency.

Cutting

The sheets are then cut into the desired size and shape for the final product.

Overall, the production of pulp and paper products is a complex process that involves a number of steps to transform raw materials into finished products.

Why Choose Shree Varudi Paper Mills?

Shree Varudi Paper Mills is a dependable producer of pulp and paper products in India, with a reputation for producing high-quality products that meet the needs of its customers. The company has a state-of-the-art production facility that is equipped with the latest technology and machinery, ensuring that its products are consistent with the highest quality.

One of the key reasons why Shree Varudi Paper Mills is a dependable producer is its commitment to sustainability. The company has implemented a number of initiatives to reduce its environmental impact, including recycling water and using renewable energy sources to power its production facility. This commitment to sustainability is reflected in the high-quality products that the company produces, which are made with care and attention to the environment.

The Largest Producer in India

With over 200 tons in production each day, Shree Varudi Paper Mills has the distinction of being the largest producer of pulp and paper products in India. The growing demand is met on a daily basis more efficiently than any other producer in the industry, thereby making them a preferred brand for industries across the world.

In conclusion, the pulp and paper industry in India is an important contributor to the country's economy, providing employment and contributing to the country's export revenue. Shree Varudi Paper Mills is a dependable producer of pulp and paper products in the country, with a commitment to sustainability and a reputation for producing high-quality products.